We have small, medium and large stone crusher for sale, stationary & mobile types for choice, meeting your different needs.

Max Feeding Size: ≤30mm

Crushing Capacity: 5-110t/h

24 hours online service

one working day reply

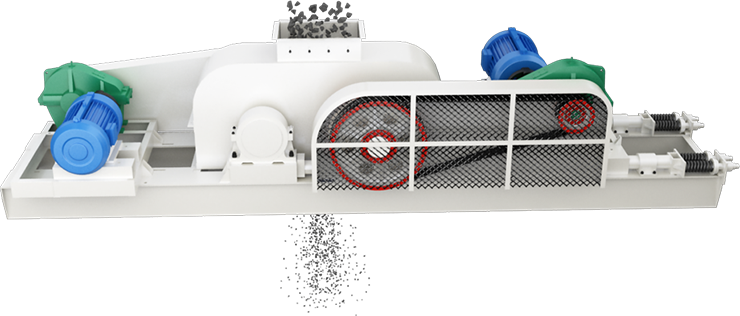

The Roller Crusher mainly crushes materials upon rotary move comparatively, since constant upgrading and improvement, it has more riper manufacturing technology. Moreover, the equipment has a simple structure, less over-crushing phenomenon, and the tooth shape, size and arrangement on the roller surface can be changed with the material properties.

Principle: mining materials are crushed by the roller wheels when they squeeze each other.

Main processing materials: coal (it also could be used in sand making, but has a smaller capacity than sand making machine.)

It is widely used in coal ore, cement, metallurgy, chemistry, building materials for sand making of the medium and fine crushing of ores and rocks with medium-hardness.

For roller adopts two sets of single drive roller, when users start the crusher, two rollers rotate along the relative direction, forming a "V" type of crushing cavity. The materials from the hopper are sent into the crusher in a suitable quantity, then enter the two rollers along the tangential direction. Due to the gap in the middle of the two rollers is small, and the system strength is greater than the material (but the high hardness material would not make the gap between rollers get larger or change the operation state of the rolling road), so the materials squeezed in the middle of the two rollers will be crushed into smaller particle size with the rotation of the roller, and then enter the bottom of the machine with the rotation of the roller, and flow out of the machine from the slotted groove to complete the whole crushing process.

In addition, the distance between the two rolls of the crusher is the width of the discharging mouth, which determines the acceptable size of the crushed material.

The discharging granularity often is the big concern for customers, because many manufacturers would produce rough granularity, which badly influences products’ quality, to solve these problems, our HXJQ optimizes the Roller Crusher, and achieve the automatic control on adjusting feeding size, in which wedge-shaped adjusting device is arranged in the middle of the two roller wheels, and an adjusting bolt is arranged at the top of the wedge-shaped device. The user can adjust the bolt to pull the wedge up or down to adjust the granularity of the material, which greatly meets the diverse needs of users on the granularity of the product and improves the quality of the product.

The Roll Crusher is mainly composed by roll wheels, bearings supporting roll wheels, pressing, adjusting and driving units.

The top of the wedge device is equipped with an adjusting bolt. When the adjusting bolt pulls the wedge up, the wedge will move to the top of the roll wheel away from the fixed wheel, that is, the gap between the two rolls becomes larger and the discharge grain size becomes larger. When the wedge is down, the gap between the two rolls becomes smaller under the action of the pressing spring, and the discharge grain size becomes smaller.

By two motors, through the triangular belt drive to the groove wheel to drag the roll wheel, in accordance with the relative direction of motion rotation. When crushing the material, the material passes through the roll from the feed port and is crushed by rolling, and the finished product after crushing is discharged from the bottom frame.

The whole machine is made of high quality wear-resistant materials, especially the roller, the roller can be used repeatedly, the failure rate is low, can bring long-term benefits for users.

The Roll Crusher can achieve “larger crushing rate, less crushing times”by reducing feeding size and quality standard of mineral materials, which has improved products’shape, as well as enhance its crushing quality, actualizing the purpose of high capacity and low consumption.

Our company still have other popular stone crusher type, like Single Cylinder Cone Crusher, Jaw Crusher, Hammer Crusher, PCZ Hammer Crusher.

If you are interested in our products, please email us at inquiryhxjq@hxjq.com

Get QuoteProduction advantages: the Roller Crusher only needs a small working area, and is easy to mobile, which effectively save much cost for users. It acquires a reasonable design, whose motor is separated from the crushing chamber to avoid corrosion or collision damage to the motor. The main feature is that it can crush materials with less than 8% moisture content so that they will not be blocked.

Crushing material: coal

Capacity: 60-110t/h

Model: 2PG1560

Feeding size: ≤50mm

Location: South Africa

Motor power: 110*2KW

We have established many successful projects in Africa, Get your solution now

The crushed stones can be used as aggregate in construction, building, road ,highway, railway and other industries. The high crushing efficiency and high quality final product meet the market demands, bringing economic benefits.

construction

railway

concrete

bridge

| Model | Input Size (mm) |

Processing capacity (t/h) |

| 2PG0425 | ≤25 | 3-10 |

| 2PG0640 | ≤25 | 5-20 |

| 2PG0740 | ≤25 | 10-30 |

| 2PG0850 | ≤25 | 15-40 |

| 2PG1060 | ≤30 | 20-50 |

| 2PG1260 | ≤30 | 25-70 |

| 2PG1560 | ≤30 | 30-110 |

| Model | Max. Feeding Size (mm) |

Discharging size(mm) |

Output (t/h) |

| 2PGC600×500 | 200-450 | 15-100 | 30-60 |

| 2PGC600×800 | 300-600 | 20-120 | 60-100 |

| 2PGC800×1000 | 500-800 | 30-150 | 100-160 |

| 2PGC1000×1000 | 700-950 | 30-200 | 150-200 |

| 2PGC1200×1200 | 800-1050 | 30-200 | 180-250 |

| 2PGC1500×1200 | 1000-1150 | 30-200 | 200-300 |

As leading stone crusher manufacturer and exporter in China, we have three large sized workshops , over 2000 staffs, more than 600 sets of large and medium-sized digital processing equipment, which guarantee the product quality and long service life of the machine.

We will provide you one-stop solution and full service system, meeting your needs.

Please feel free to fill in the form or email us at inquiryhxjq@hxjq.com, get product information,price, We will reply to you within 24 hours as soon as possible.

Within 24 Hours Email Reply

Factory-direct Sale, Fast Delivery

Company and Factory Visit