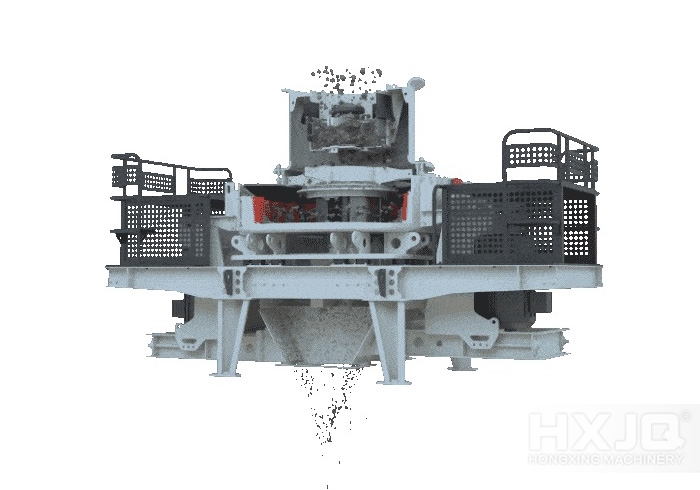

Notices on Sand Making Machine

2021/06/29 10:03:43Hongxing machinery

Contact usNatural sand and gravel are gradually reduced, and artificial sand will gradually replace them. There would inevitably be some problems in using the new type sand making machine, for the working condition is relatively bad, and its surface would be rusted, thus causing severe influences towards its quality. Therefore, we are required to pay attention to the point, and today we will share some tips on rust prevention and derusting concerning the sand maker.

First of all, I would like to recall that most mining equipment, such as sand-making machines, crushers, and pulverizers, is made of iron and steel. After a long period of open-air operation or influenced by abundant water vapor, rust is a very normal chemical reaction. There have been several main ways to be as follows.

Rust Prevention

1. Electroplating and Heat:Metal materials, such as aluminum and zinc, which are not easy to rust on the surface of the Sand Maker by electroplating or heating, can form a compact oxide film on the surface of the machine so that it could prevent contact from being rust between the sand maker and water, air.

2. Coating method: Coating oily materials and paint on the surface of the sand making machine can insulate the sand making machine from the external water and oxygen, so as to avoid oxidation and rust of the machine.

Derusting

1. Chemical derusting method: it is a derusting method that mainly uses the chemical reaction between the acid and metal oxide to remove the rust on the metal surface of efficient sand making machine, that is, Acid Pickling, which can only be operated in the workshop;

2. High-pressure water abrasive derusting method: It depends on the impact of high-pressure water (plus the grinding effect of abrasive) and water trying to remove the rust and coating on the steel plate of sand making machine. It has no dust pollution, no damage to a steel plate, and greatly improve the efficiency and quality of rust removal, up to 15 square meters per hour.

3. Small scale pneumatic or electric derusting method: it is mainly powered by electricity or compressed air and equipped with appropriate derusting device to carry out reciprocating or rotary motion to meet the derusting requirements on various occasions.

Maintenance

It is critical that it should be maintained from time to time, when the equipment is in use or idle, which can not be neglected. The equipment with good performance is a symbol of bringing benefits to the enterprise.

1. Shut down the machine and open the observation door to check conditions of internal wear of Impact Sand Maker, and the wear degree of the center feeding pipe, cone cap, upper and lower flow channel lining plates of the impeller, circumferential guard plate, and wear block. If anyone gets worn, it should be replaced or repaired in time, the wear block should be replaced at the same time to ensure the uniform weight of the rear block. It is formally forbidden to open the observation door to observe the internal working condition during the operation of the crusher, to avoid danger. If the impeller body is worn, please replace it in time and find the manufacturer to repair it. Special attention, without the consent of the manufacturer, users mustn’t produce the impeller

2. Adjust the V-belt to assure the uniform force on the V-belt properly. When the V-belt is driven by two motors, the V-belts on both sides should be selected in groups to make the length of each group as consistent as possible, to guarantee the energy-saving and high efficiency of the sanding machine equipment;

3. Add some grease, when the sanding machine works for 400 hours. When it works for 2000 hours, it is necessary to open the spindle mechanism for cleaning. If it works for 7200 hours, it should be replaced with a new bearing.