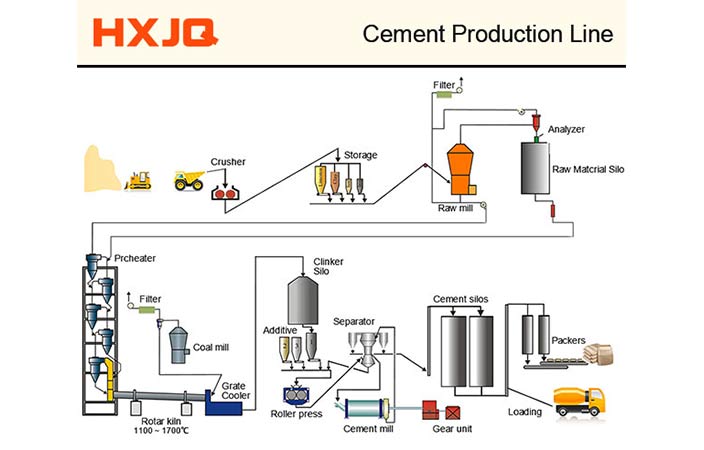

Cement Plant Production Line

Three large sized workshops, strict quality control system and decades of years production technology make cement production plant better performance, higher crushing efficiency and longer service life.Processing Material: limestone, bauxite, cement clinker, etc.

Quote Online Email Reply Customized Solution Product Delivery Transportation time After-sales Service

First Within 24 Hours 1-2 weeks 15-45 days 5-50 days (based on destination) Any time

Above is main procedure, if interest, please email us to

inquiryhxjq@hxjq.com